Dual-spindle, Dual ATC, Dual Z Axis design double raises machining efficiency. Integrated design optimizes the machine structure with reasonable layout, which brings better rigidity and higher reliability. Adapting pre-load technology on ballscrew realizes higher transmission accuracy and longer working service.

Dual-spindle, Dual ATC, Dual Z Axis design double raises machining efficiency. Integrated design optimizes the machine structure with reasonable layout, which brings better rigidity and higher reliability. Adapting pre-load technology on ballscrew realizes higher transmission accuracy and longer working service.

Machine Characteristics

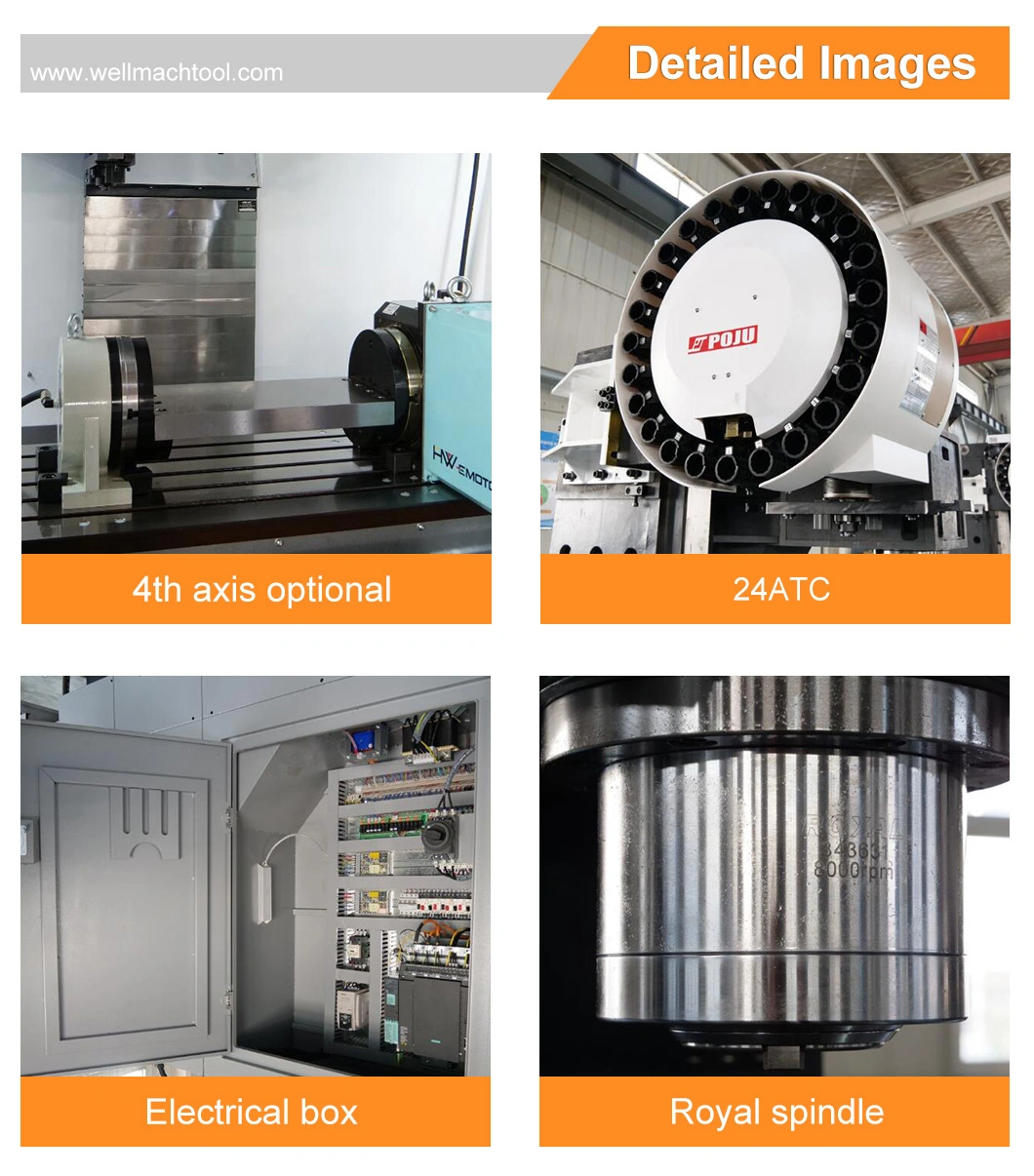

1.Heavy duty LM guideway support bearing

2.Larger motor power

3.Large guideway span

4.Heavier machine weight

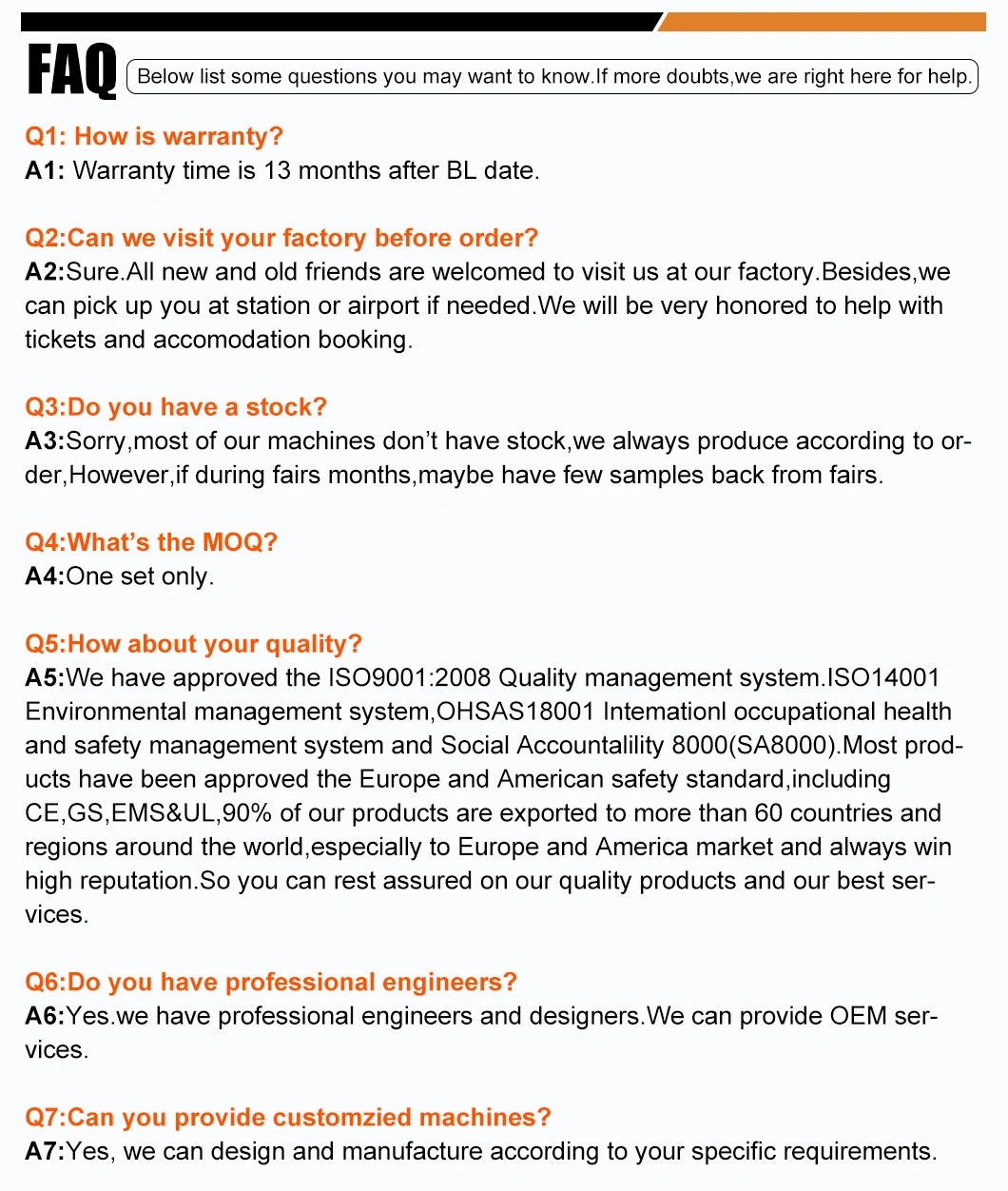

5.BT40-150 type big spindle with 8000rpm

| Specifications | DVMC-D8 |

| Worktable size | 1300×520mm |

| T-slot | 18×5×90mm |

| Max. loading of worktable | 600kg |

| Spindle center to column distance | 580mm |

| Spindle nose to table distance | 130-700mm |

| Rail type | Linear Guideway |

| Spindle taper | BT40 |

| Spindle speed | 8000/12000rpm |

| Main motor power | 7.5/11kw |

| X axis travel | 650mm |

| Y axis travel | 500mm |

| Z axis travel | Z1:570 Z2:570mm |

| X/Y/Z rapid traverse | 30000mm/min |

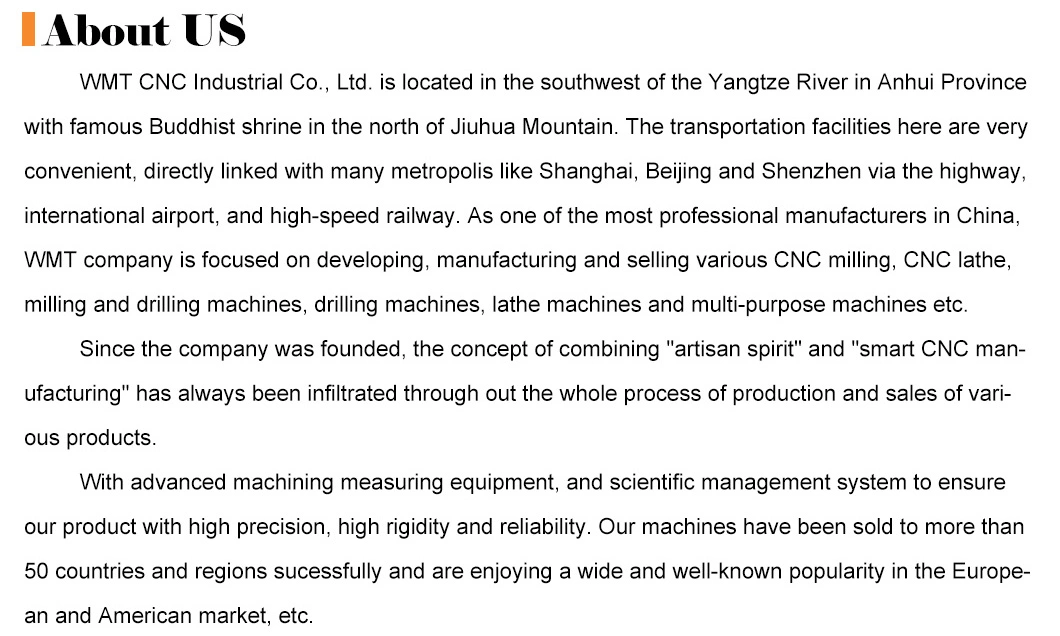

| Tool magazine capacity | 24* |

| Max.weight of tool | 8* |

| Positioning accuracy | ±0.006mm |

| Re-positioning accuracy | ±0.003mm |

| Air pressure | 0.5-0.8mpa |

| Coolant | air conditioning |

| Overall dimension(LxWxH) | 3250×2800×2950mm |

| Weight | 7500kgs |