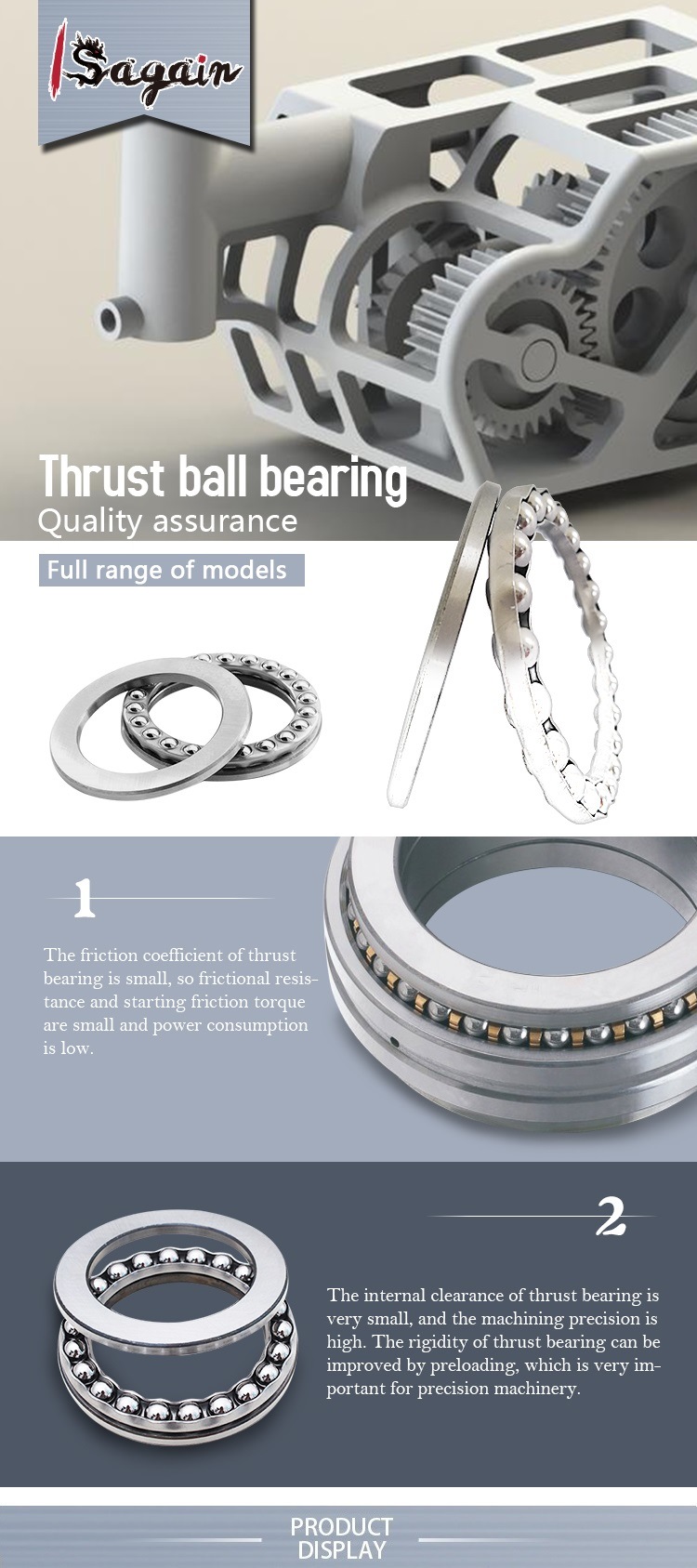

Description on Thrust Ball Bearings:

1. Description

Thrust ball bearing is a separate bearing, the contact ball is 90°, this kind of bearing is composed of inner ring, outer ring and retainer. Single-row thrust ball bearing can carry axial load from single direction.

Two-row thrust ball bearing can carry axial load from double direction. Thrust ball bearing with spherical rings has aligning performance, which can eliminate installation error.

Thrust ball bearings are produced as single direction or double direction thrust ball bearings. They are designed to accommodate axial loads only and must not be subjected to any radial load.

Thrust ball bearings are separable, i.e. the shaft washer, housing washer(s), ball and cage assembly(s) can be mounted separately. Shaft washers have a ground bore to enable an interference fit. The bore of the housing washer is turned and always larger than the shaft washer bore.

2. Structure

Single-row thrust ball bearing

Double-row thrust ball bearing

CHIK Single Direction Thrust Ball Bearings consist of two flat washers with raceways, balls and cage which are detachable. The washers have a flat seating surface therefore they have to be embedded so that all balls are equally loaded. Bearings only transfer axial loads in one direction.

3. Cage

Steel stamping cage, machine solide cage(brass) Thrust ball bearings have as standard pressed steel cage, where the material and application is not marked. Larger size bearings use massive brass cage to offer more robust solutions.

4. Features

CHIK thrust ball bearings are design to accommodate large axial load, however they must not be subjected to radial load. Most frequent bearings are single direction thrust ball bearings. During operation these bearings must be constantly subjected to a specific axial load. These bearings can be also combined with spherical rings to cope with small initial misalignments.

| ISO | Dimensions (mm) | Basic Load Rating (N) | Limitting speed ( r/min ) | Weight | ||||

| Lubrication | ||||||||

| d | D | B | Dyn. C | Stat. C0 | Grease | Oil | ||

| 51100 | 10 | 24 | 9 | 10000 | 14000 | 7000 | 9500 | 0.02 |

| 51101 | 12 | 26 | 9 | 10400 | 15300 | 6700 | 9000 | 0.022 |

| 51102 | 15 | 28 | 9 | 10600 | 16600 | 6300 | 8500 | 0.023 |

| 51103 | 17 | 30 | 9 | 11400 | 19600 | 6300 | 8500 | 0.025 |

| 51104 | 20 | 35 | 10 | 12700 | 20800 | 5600 | 7500 | 0.038 |

| 51105 | 25 | 42 | 11 | 15900 | 29000 | 4800 | 6300 | 0.056 |

| 51106 | 30 | 47 | 11 | 16800 | 33500 | 4500 | 6000 | 0.063 |

| 51107 | 35 | 52 | 12 | 17400 | 37500 | 4300 | 5600 | 0.08 |

| 51108 | 40 | 60 | 13 | 23400 | 50000 | 3800 | 5000 | 0.12 |

| 51109 | 45 | 65 | 14 | 24200 | 57000 | 3400 | 4500 | 0.14 |

| 51110 | 50 | 70 | 14 | 25500 | 63000 | 3200 | 4300 | 0.16 |

| 51111 | 55 | 78 | 16 | 30700 | 78000 | 2800 | 3800 | 0.247 |

| 51112 | 60 | 85 | 17 | 36400 | 93000 | 2600 | 3600 | 0.33 |

| 51113 | 65 | 90 | 18 | 37100 | 98000 | 2400 | 3400 | 0.359 |

| 51114 | 70 | 95 | 18 | 37700 | 104000 | 2400 | 3400 | 0.385 |

| 51115 | 75 | 100 | 19 | 44200 | 137000 | 2200 | 3200 | 0.4 |

| 51116 | 80 | 105 | 19 | 44900 | 140000 | 2000 | 3000 | 0.42 |

| 51117 | 85 | 110 | 19 | 46200 | 150000 | 2000 | 3000 | 0.44 |

| 51118 | 90 | 120 | 22 | 59200 | 190000 | 1800 | 2600 | 0.67 |

| 51120 | 100 | 135 | 25 | 85200 | 270000 | 1700 | 2400 | 0.97 |

| 51122 | 110 | 145 | 25 | 87100 | 290000 | 1600 | 2200 | 1.05 |

| 51124 | 120 | 155 | 25 | 88400 | 310000 | 1600 | 2200 | 1.15 |

| 51126 | 130 | 170 | 30 | 111000 | 390000 | 1400 | 1900 | 1.85 |

| 51128 | 140 | 180 | 31 | 112000 | 400000 | 1300 | 1800 | 2.05 |

| 51130 | 150 | 190 | 31 | 112000 | 400000 | 1200 | 1700 | 2.2 |

| 51132 | 160 | 200 | 31 | 112000 | 425000 | 1200 | 1700 | 2.35 |

| 51134 | 170 | 215 | 34 | 133000 | 500000 | 1100 | 1600 | 3.3 |

| 51136 | 180 | 225 | 34 | 135000 | 530000 | 1000 | 1500 | 3.5 |

| 51138 | 190 | 240 | 37 | 172000 | 655000 | 950 | 1400 | 4.05 |

| 51140 | 200 | 250 | 37 | 174000 | 655000 | 950 | 1400 | 4.25 |

| 51144 | 220 | 270 | 37 | 178000 | 735000 | 900 | 1300 | 4.6 |

| 51148 | 240 | 300 | 45 | 234000 | 965000 | 800 | 1100 | 7.55 |

| 51152 | 260 | 320 | 45 | 238000 | 1020000 | 800 | 1100 | 8.1 |

| 51156 | 280 | 350 | 53 | 319000 | 1460000 | 700 | 950 | 12 |

| 51160 | 300 | 380 | 62 | 364000 | 1760000 | 630 | 850 | 17.5 |

| 51164 | 320 | 400 | 63 | 371000 | 1860000 | 600 | 800 | 19 |

| 51168 | 340 | 420 | 64 | 377000 | 1960000 | 600 | 800 | 20 |

| 51172 | 360 | 440 | 65 | 390000 | 2000000 | 560 | 750 | 21.8 |

| 51176 | 380 | 460 | 65 | 398000 | 2180000 | 550 | 750 | 22.75 |

| 51180 | 400 | 480 | 65 | 403000 | 2250000 | 520 | 720 | 24 |

| ISO | Dimensions (mm) | Basic Load Rating (N) | Limitting speed ( r/min ) | Weight | ||||

| Lubrication | ||||||||

| d | D | B | Dyn. C | Stat. C0 | Grease | Oil | ||

| 51200 | 10 | 26 | 11 | 12700 | 17000 | 6000 | 8000 | 0.031 |

| 51201 | 12 | 28 | 11 | 13300 | 19000 | 6000 | 8000 | 0.034 |

| 51202 | 15 | 32 | 12 | 16500 | 25000 | 5300 | 7000 | 0.046 |

| 51203 | 17 | 35 | 12 | 17200 | 27500 | 5000 | 6700 | 0.053 |

| 51204 | 20 | 40 | 14 | 22500 | 37500 | 4500 | 6000 | 0.083 |

| 51205 | 25 | 47 | 15 | 25500 | 47500 | 4000 | 5300 | 0.11 |

| 51206 | 30 | 52 | 16 | 26700 | 50000 | 3600 | 4800 | 0.13 |

| 51207 | 35 | 62 | 18 | 35100 | 67000 | 3000 | 4000 | 0.22 |

| 51208 | 40 | 68 | 19 | 46800 | 98000 | 2800 | 3800 | 0.28 |

| 51209 | 45 | 73 | 20 | 39000 | 80000 | 2600 | 3600 | 0.3 |

| 51210 | 50 | 78 | 22 | 49400 | 106000 | 2400 | 3400 | 0.37 |

| 51211 | 55 | 90 | 25 | 61800 | 134000 | 1900 | 2800 | 0.59 |

| 51212 | 60 | 95 | 26 | 62400 | 140000 | 1900 | 2800 | 0.65 |

| 51213 | 65 | 100 | 27 | 63700 | 150000 | 1800 | 2600 | 0.78 |

| 51214 | 70 | 105 | 27 | 65000 | 160000 | 1800 | 2600 | 0.79 |

| 51215 | 75 | 110 | 27 | 67600 | 170000 | 1700 | 2400 | 0.83 |

| 51216 | 80 | 115 | 28 | 76100 | 190000 | 1700 | 2400 | 0.91 |

| 51217 | 85 | 125 | 31 | 97500 | 250000 | 1600 | 2200 | 1.2 |

| 51218 | 90 | 135 | 35 | 119000 | 300000 | 1500 | 2000 | 1.7 |

| 51220 | 100 | 150 | 38 | 124000 | 320000 | 1300 | 1800 | 2.2 |

| 51222 | 110 | 160 | 38 | 130000 | 360000 | 1200 | 1700 | 2.4 |

| 51224 | 120 | 170 | 39 | 140000 | 400000 | 1100 | 1600 | 2.65 |

| 51226 | 130 | 190 | 45 | 186000 | 540000 | 950 | 1400 | 4 |

| 51228 | 140 | 200 | 46 | 190000 | 570000 | 950 | 1400 | 4.35 |

| 51230 | 150 | 215 | 50 | 238000 | 735000 | 900 | 1300 | 6.1 |

| 51232 | 160 | 225 | 51 | 242000 | 780000 | 850 | 1200 | 6.55 |

| 51234 | 170 | 240 | 55 | 286000 | 930000 | 800 | 1100 | 8.15 |

| 51236 | 180 | 250 | 56 | 296000 | 1000000 | 800 | 1100 | 8.6 |

| 51238 | 190 | 270 | 62 | 332000 | 1160000 | 750 | 1000 | 11.7 |

| 51240 | 200 | 280 | 62 | 338000 | 1220000 | 750 | 1000 | 12 |

| 51244 | 220 | 300 | 63 | 351000 | 1320000 | 700 | 950 | 13 |

| 51248 | 240 | 300 | 45 | 462000 | 1980000 | 600 | 800 | 23 |

| 51252 | 260 | 360 | 79 | 470000 | 2100000 | 560 | 780 | 25.2 |

| 51256 | 280 | 380 | 80 | 492000 | 2320000 | 550 | 750 | 26.5 |

5. Application

Machine spindle, worktable of vertical lathe, auto steering mechanism, Fluid control valves

Machine tool tables and spindles

Oil and gas rotary tables

Screw Jacks

6. Product Details:Structure: Thrust ball bearing

Precision level: P0-P6

Vibration: V1-V3

Seal type: U U/T

Number of row: Single row

Cage material: Brass, steel, nylon

Double pressed cage.

Bearing code: 29320

Type: Thrust Roller Bearing

Cage: Brass/Steel/Nylon

Material: Carbon steel/stainless steel/chrome steel

Standard: ISO9001

Precision: P6/P5/P4/P2/P0

Clearance: C3/C4

Noise: Low noise

Speed: High speed

Life: 2-3 years

7. Advantages:

(1) Fast delivery

(2) Long working life

(3) Perfect compensation system

(4) Competitive price and high quality

(5) Different famous brand

(6) Flexible payment term

(7) Good and instant after market service

(8) Much experience of trade business

8.Our Company

As a comprehensive industrial enterprise that integrates R & D and sales services, with over 20 years' experience, especially the guaranteed supplier of China Manufacturing Network, our factory covers an area of 10,000 square meters, which enables very quick delivery.

Owning the most advanced CNC automatic production line, automatic assembly line, and a varied of testing equipment, our bearings mainly cover SKF, NSK, NTN, KOYO, TIMKEN, NACHI, THK etc., which meets all low noise, low vibration, low friction, high precision, high sealed, high turning speed and long life requests.

9. FAQ

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3.It's better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 5000 pcs customized your brand bearings.

OEM POLICY

1.We can printing your brand (logo,artwork)on the shield or laser engraving your brand on the shield.

2.We can custom your packaging according to your design

3.All copyright own by clients and we promised don't disclose any info.

SUPPORT

Please visit our 1Sagain bearings website, we strongly encourage that you can communicate with us through email, thanks!